SKU:1000786

A60 15 x 22mm Push-In Aluminium Wood Effect Stair Nosing Edge Trim

A60 15 x 22mm Push-In Aluminium Wood Effect Stair Nosing Edge Trim

In stock

Couldn't load pickup availability

- Secure Payment Methods

- Free Shipping Spend £300 or more

- Dispatch Same Day (Ordered Before 2 PM Mon-Thu)

Need Help? sales@stairsnosinguk.uk | +44 7401 774123

A60 15 × 22mm Push-In Aluminium Wood-Effect Stair Nosing Edge Trim

Compact push-in stair nosing designed to protect and finish step fronts with a natural wood look — ideal for quick retrofits and new builds where you want a neat, screw-free appearance. Perfect for laminate, LVT, engineered wood or vinyl stair treads, especially where a small, discreet nosing is required.

Key specifications & use case

- Product type: Push-in / press-fit stair nosing edge trim

- Use case: Protects and defines stair leading edges; retro-fit or new install where visible fixings are undesired

- Material: Aluminium core with durable wood-effect surface layer

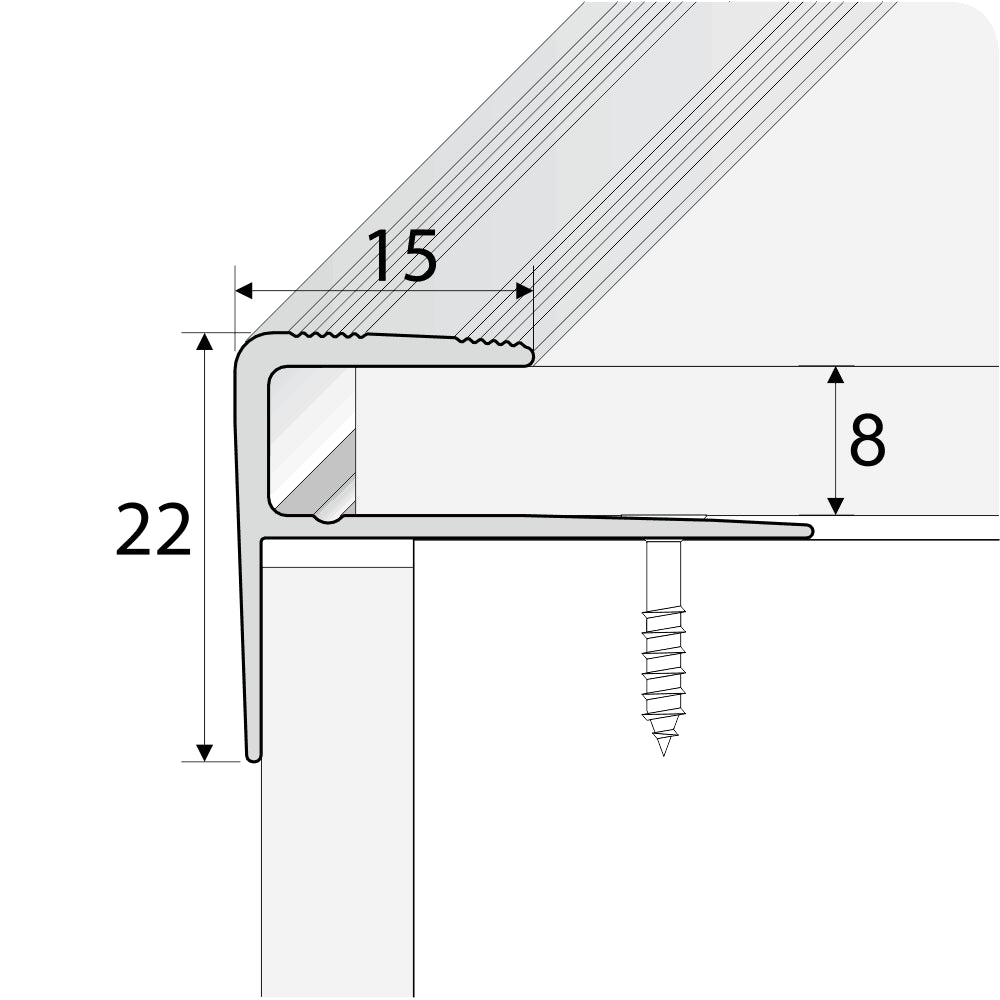

- Dimensions: 15 mm tread coverage × 22 mm riser/drop (approx.)

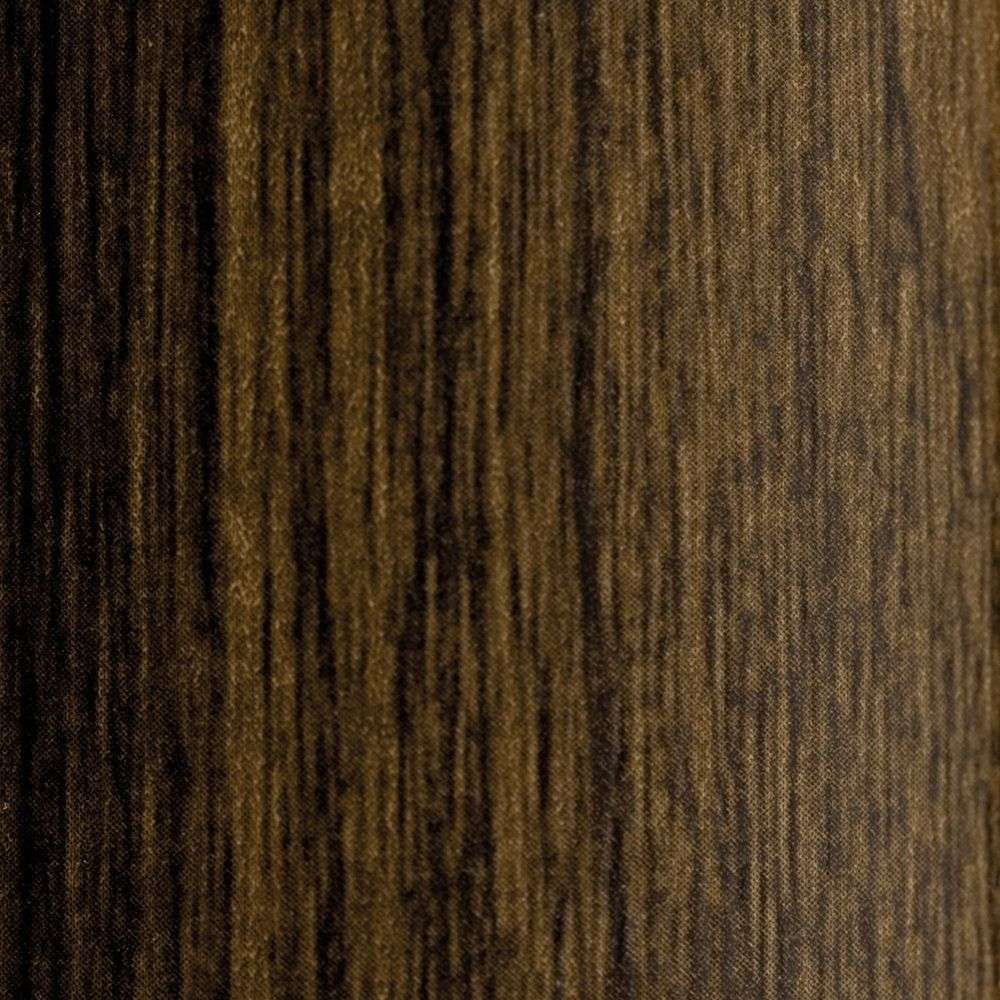

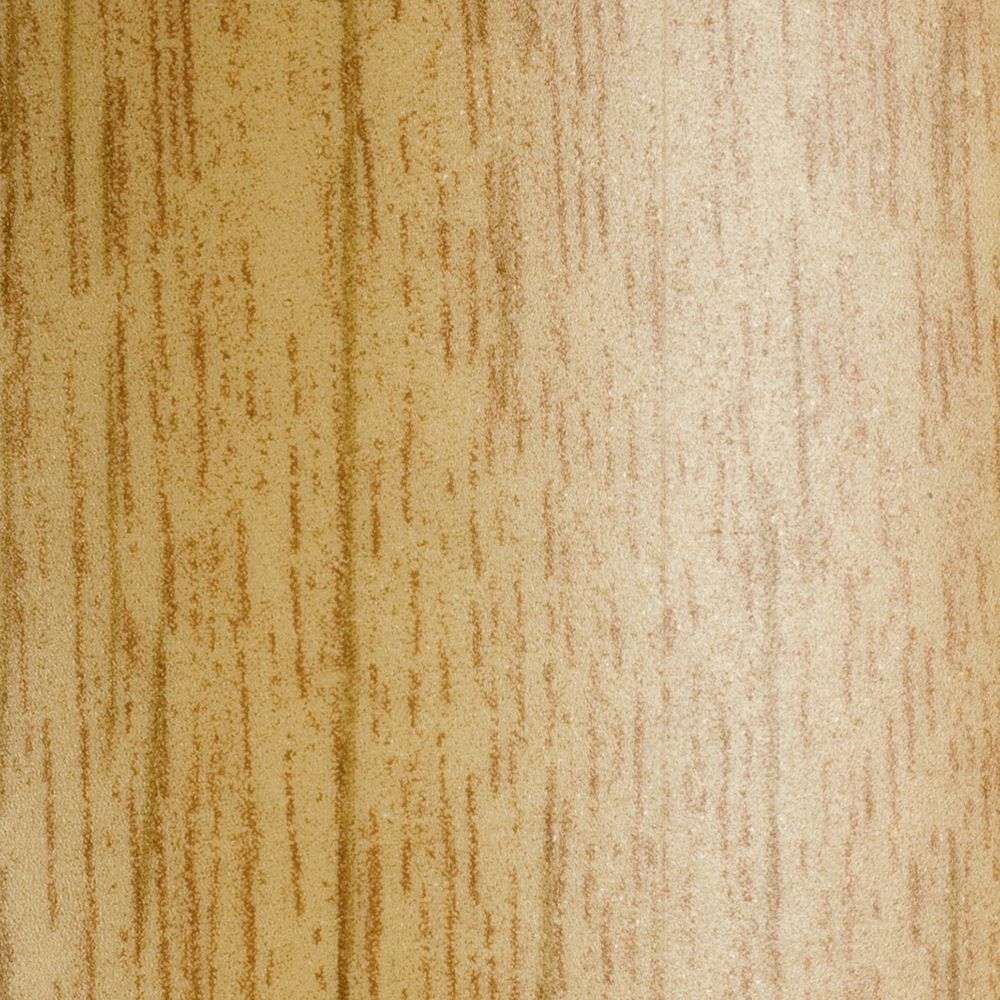

- Colour / finish: Realistic wood-grain finish (multiple tones available); low-sheen, wipe-clean surface

- Installation: Push-in into compatible channel/base or prepared seat — no visible screws

Benefits

- Clean, no-screw look: Push-in system gives a seamless finish with no visible fixings.

- Improved safety: Defines the step edge to reduce trips and improve foot placement.

- Durable core: Aluminium core resists dents and maintains shape under traffic.

- Aesthetic match: Wood-effect face complements laminate, LVT and engineered wood for a continuous look.

- Low maintenance: Wipe-clean surface that requires no varnishing or sealing.

Quick-scan bullets

- Push-in, screw-free retrofit or new-fit nosing

- 15 × 22 mm compact profile for discreet edges

- Aluminium strength with wood-effect surface

- Ideal for laminate, LVT, vinyl & engineered wood treads

- Low-sheen, wipe-clean finish; easy to cut to length

FAQ

Q: Do I need a special channel or can I fit directly to the stair?

A: Push-in nosings typically require a compatible base channel or a prepared recessed seat for a secure press-fit. Some installers create a shallow routed seat or use the manufacturer’s base track. If no channel is used, ensure the seat is square, clean and properly sized so the nosing engages firmly; adhesive can be used in addition for extra security on challenging substrates.